45 Degree Long Radius Elbow

Classification :

PRODUCT DETAILS

Keywords: Steel Plate, Steel Coil , Ductile Iron Pipe

The difference between stainless steel elbow and carbon steel elbow is mainly the difference of the material, the chemical composition will keep the surface of the elbow for a long time will not rust, will not be corroded.

In piping systems, an elbow is a pipe fitting that changes the direction of the pipe.According to the Angle, there are 45° and 90°180° three most commonly used, and according to the engineering needs, there are also 60° and other abnormal Angle elbows.

| Standard: | ASTM EN DIN GB ISO JIS | Certification: | SGS,ISO,ROHS |

| Size: | 1/2"-24" seamless, 26"-60" welded | Polish: | mirror polish,dull/matte polish,sub-light,240 girt,400 grit |

| Wall thickness: | SCH5S, SCH10S, SCH10, SCH40S, STD, XS, SCH80S, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS and etc. | Surface: | Pickled,sand blasting, rolling blast,brighten,matt polished,mirror polished,vanished,shinning |

| Radius: | LR/long radius/R=1.5D,SR/Shrot radius/R=1D, various radius: 3D,4D,5D,6D,7D,10D,20D etc. | Process Method: | Forged / Casting |

| End: | Bevel end/BE/buttweld | Price terms: | FOB,CRF,CIF,EXW all acceptable |

| Camber: | 30° 45° 60° 90° 180°,etc | Payment Terms: | T/T, L/C at sight,West Union,D/P,D/A,Paypal |

| Grade: | 201,202,304,304L,309,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420(420J1,420J2),430,436,439,441,444,446 etc1.4301, 1.4307, 1.4541, 1.4401, 1.4404 ,1.4571, 1.4438, 1.4539, 1.4547, 1.4529, 1.4562, 1.4410, 1.4878, 1.4845, 1.4828, 1.4876, 2.4858, 2.4819 | ||

| Application: | Petrochemical and chemical company, Fertilizer Industry, electric power, shipbuilding, papermaking, construction, offshore platform, Refinery Industry, etc | ||

| Container Size: | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) | ||

Elbow materials are cast iron, stainless steel, alloy steel, calcined cast iron, carbon steel, non-ferrous metals and plastics, etc.Pipe connection methods are: direct welding (the most common way) flange connection, hot melt connection, electric fusion connection, threaded connection and socket connection.According to the production process, it can be divided into: welding elbow, stamping elbow, hot pressing elbow, push elbow, casting elbow, forging elbow, clamp elbow, etc.Other names: 90° bend, right Angle bend, love bend, white steel bend, etc.

According to the standard production can be converted into:

1. According to the manufacturing standard, it can be divided into national standard, ship standard, electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

2. It can be divided into pushing, pressing, forging, casting and so on.

90° stainless steel elbow is mainly used for pipe installation in a connecting pipe fitting, for pipe bend connection.Connect two pipes of the same or different nominal diameter to make a 90° turn.

Usually on the basis of carbon steel increased a high proportion of Cr, Ni and other alloys, the content ratio can reach more than 20%.Common types of steel are: 304,304L, 321,316,316L, 1Cr18Ni9Ti, 0Cr18Ni9, the first several numerical representation of steel number for Japan, the United States steel number method, the last one (1Cr18Ni9Ti) for the domestic steel number method.

Stainless steel characteristics: strength, toughness index is the best of all kinds of steel, its most prominent advantage is corrosion resistance, in chemical paper and other corrosive occasions must use stainless steel, of course, the cost is also high!

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Quality inspection

Advanced testing equipment and methods are used to conduct comprehensive testing of key indicators such as size, hardness, and toughness of the product. Track the entire production process to ensure that every process meets quality requirements

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision Processing, auto parts, machinery, electronic products, molds, medical equipment, construction, decoration, etc.

CUSTOMER VISIT

Due to our continuous and widespread success in overseas market and outstanding social contributions, our company was awarded by the local government for many times. Our products have been exported to Southeast Asia, Middle east, South America, Europe, Oceania and other countries and regions, which enjoys good reputation.

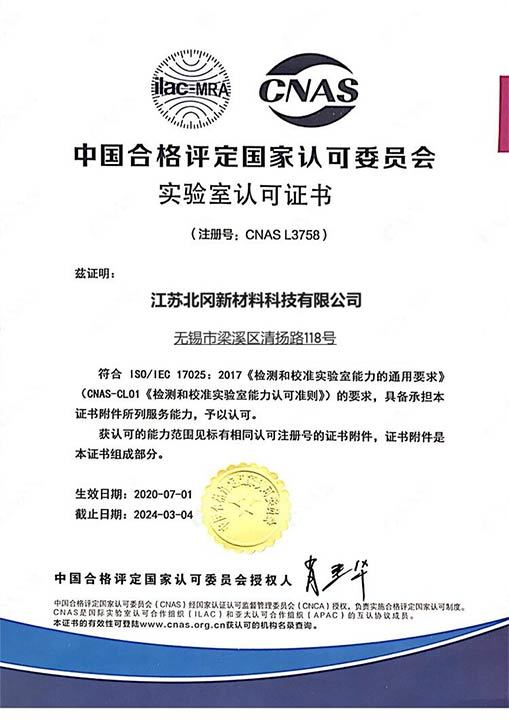

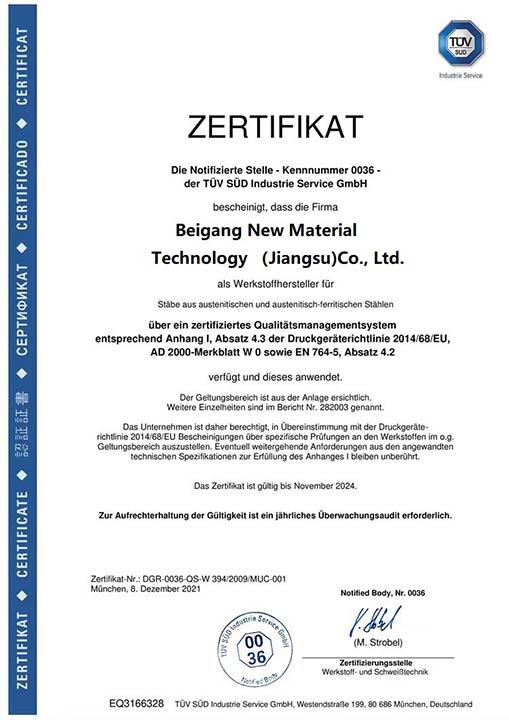

QUALIFICATION CERTIFICATES AND HONORS

FAQ

Q: What is your MOQ?

Q: What is the delivery time?

Q: What kind of payment terms would you accept?

Q: What certifications do your products have?

Q: Do you provide samples Is it free or extra?

Q: Once the products received by customer were found not comply with the products or contract demands, what will you do?

RELATED PRODUCTS

GET A FREE QUOTE