Casing And Tubing Coupling

Classification :

PRODUCT DETAILS

Keywords: Steel Plate, Steel Coil , Ductile Iron Pipe

Description

About Tubing coupling

Normally tubing coupling OD maximum is 4 1/2”, as the tubing pipe is applied for the drilling activities (Inside the tubing is the sucker rod to drill/pump the oil), couplings type is more various and rigorous than casing, mostly used is thicken type upset coupling (Internal upset and external upset), for short is EUE coupling, it is the most favorable in tubing connections. Tubing with EU end (EUE) coupling connection also called UPTBG. Because of the end of the tubing is thickened (upset), the connecting stress is better than buttress coupling.

Buttress coupling another type used for tubing connections, it has the same thickness of the pipe body, called NU end (NUE)tubing or TBG.

Features

The oil tubing coupling can solve the problem of fatigue fracture in the existing coupling due to stress concentration. Oil tubing end is connected to the inside wall of the coupling in a tapered thread. The coupling body end and oil tubing are connected with same thread pitch flat thread. The coupling is not easy to produce fatigue fracture, and has good connection effect. It can prevent the accident of oil well pipe string break effectively.

About Casing coupling

Casing coupling is for the dimensions more than 4 1/2 inch. Differently than tubing coupling is, casing coupling normally does not need to be thickened (Non-upset), which means no upset casing coupling, so it has following types:

• BTC: Buttress coupling

• LTC: Long buttress coupling

• STC: Short buttress coupling

All three types has same thickness of the casing pipe body, just have different lengths.

The oil casing coupling is a necessary piece used to connect the two casing. The coupling manufacturing method is the same as seamless pipe. The steel pipe ends with internal thread to connect with the upper and lower casing. In order to ensure the joint tightness, the precision of screw thread is strictly required.

Seamless and ERW Casing

|

Specification |

API 5CT |

|

Grades |

K55, N80, L80, C95, P110, Chrome, J55(Modified), J55 (API), PS80 |

|

Special Grades |

For sour services and for deep well with high collapse properties |

|

Dimensions |

OD 4" - 26" WT - 0.2 -0.5" |

|

Length range |

1, 2 or 3 |

|

Thread connections |

API (STC and LTC), BTC, extreme line, etc. |

Seamless and ERW Tubing

|

Specification |

API 5CT |

|

Grades |

J55 (API) J55(Modified), N80, L80, L80 13Cr, P110, Q125, H40 (API) |

|

Thread connections |

API 5B - Last Edition or Premium, EUE, NUE, special seal, metal-to-metal seal and VAGT |

Specification

Casing Couplings Short Thread Specifications:

|

Casing Couplings |

Casing Size OD (inches) |

Coupling Size OD (inches) |

Length (inches) |

Weight per Coupling (lbs) |

Palletized Carton Quantity |

|

4-1/2 |

5.000 |

6.250 |

8.05 |

343 |

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Quality inspection

Advanced testing equipment and methods are used to conduct comprehensive testing of key indicators such as size, hardness, and toughness of the product. Track the entire production process to ensure that every process meets quality requirements

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision Processing, auto parts, machinery, electronic products, molds, medical equipment, construction, decoration, etc.

CUSTOMER VISIT

Due to our continuous and widespread success in overseas market and outstanding social contributions, our company was awarded by the local government for many times. Our products have been exported to Southeast Asia, Middle east, South America, Europe, Oceania and other countries and regions, which enjoys good reputation.

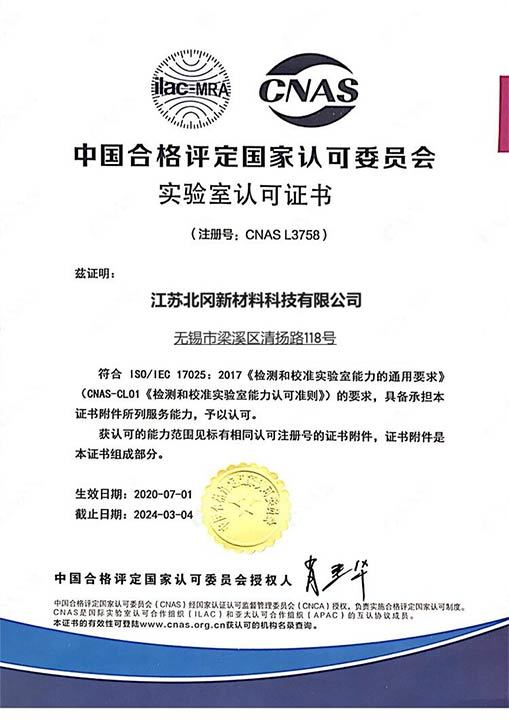

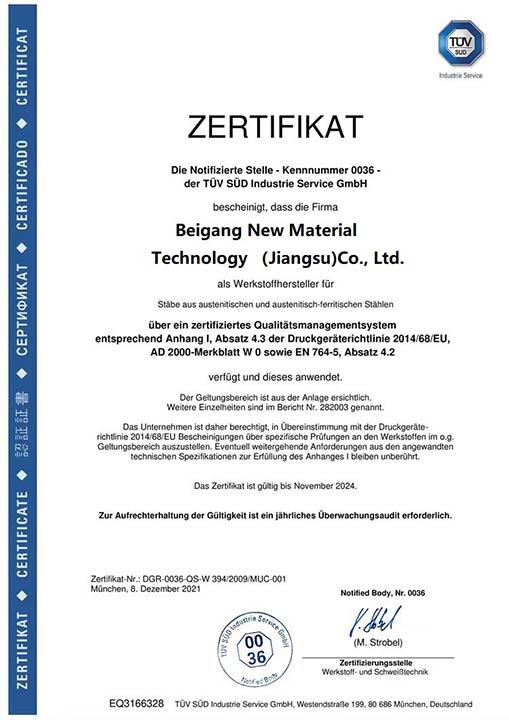

QUALIFICATION CERTIFICATES AND HONORS

FAQ

Q: What is your MOQ?

Q: What is the delivery time?

Q: What kind of payment terms would you accept?

Q: What certifications do your products have?

Q: Do you provide samples Is it free or extra?

Q: Once the products received by customer were found not comply with the products or contract demands, what will you do?

RELATED PRODUCTS

GET A FREE QUOTE