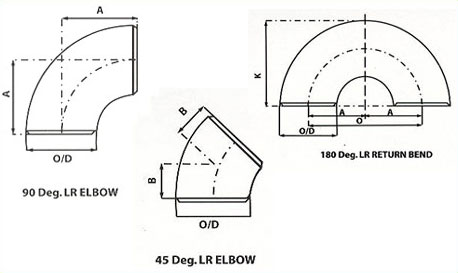

Steel Pipe Elbow

Classification :

PRODUCT DETAILS

Keywords: Steel Plate, Steel Coil , Ductile Iron Pipe

Seamless Elbow Manufacturing Process (Heat Bending & Cold Bending)

One of the most common methods for manufacturing elbows is using hot mandrel bending from straight steel pipes. After heating the steel pipe at a elevated temperature, the pipe is pushed, expanded, bended by the inner tools of mandrel step by step. Applying hot mandrel bending can manufacture a wide size range seamless elbow. The characteristics of mandrel bending are strongely depend on the intergrated shape and dimensions of the mandrel. The using advantages of hot bending elbows include smaller thickness deviation and stronger bending radius than other bending methond type. Meanwhile, using bending instead of prefabricated bends substantially reduces the number of welds needed. This reduces the amount of work required and increases the quality and usability of pipes. However, cold bending is the process to bent the straight steel pipe at normal temperatures in a bending machine. Cold bending is suitable for pipes with an outer diameter of 17.0 to 219.1 mm, and wall thickness 2.0 to 28.0 mm. The recommended bending radius is 2.5 x Do. Normally at a bending radius of 40D. By using cold bending, we can get small radius elbows, but we need to pack the internals with sand to prevent wrinkling. Cold bending is a quick and inexpensive bending method. It is a competitive option for making pipelines and machine parts.

Welded Elbow Manufacturing Process (Small & Large)

Welded elbows are made from the steel plates, so it is not seamless steel elbows. Use a mould and press the steel plate to the shape of the elbow, then weld the seam to be a finish steel elbow. It is the old production method of the elbows. Recent years the small sizes elbows are almost manufactured from the steel pipes now. For the big size elbows, for example, it is very difficult to produce elbows over 36” OD from the steel pipes . So it is commonly made from the steel plates, pressing the plate to the shape of half elbow, and welding the two halves together. Since the elbows are welded in its body , the inspection of the welding joint is necessary . Commonly we use the X-Ray inspection as the NDT.

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Quality inspection

Advanced testing equipment and methods are used to conduct comprehensive testing of key indicators such as size, hardness, and toughness of the product. Track the entire production process to ensure that every process meets quality requirements

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision Processing, auto parts, machinery, electronic products, molds, medical equipment, construction, decoration, etc.

CUSTOMER VISIT

Due to our continuous and widespread success in overseas market and outstanding social contributions, our company was awarded by the local government for many times. Our products have been exported to Southeast Asia, Middle east, South America, Europe, Oceania and other countries and regions, which enjoys good reputation.

QUALIFICATION CERTIFICATES AND HONORS

FAQ

Q: What is your MOQ?

Q: What is the delivery time?

Q: What kind of payment terms would you accept?

Q: What certifications do your products have?

Q: Do you provide samples Is it free or extra?

Q: Once the products received by customer were found not comply with the products or contract demands, what will you do?

RELATED PRODUCTS

GET A FREE QUOTE