Structural Steel Pipe

Classification :

PRODUCT DETAILS

Keywords: Steel Plate, Steel Coil , Ductile Iron Pipe

Product introduction

Structural Steel Pipe

Pipe Type: Structural Pipe, Structural Seamless Pipe, Seamless Structural Pipe

Application: In Structural Engineering and Construction Industry

Specification: OD: 1/8'' ~ 26'' (10.3 ~ 660mm)

WT: SCH 10 ~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL

Standard: ASTM A53/A252/A500/A501, JIS G3444, EN 10210/10219

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Specification of Structural Steel Pipe

| API 5L/ASTM A106 GR.B, Structural Steel Pipe | ||||

| 公称通径 DN |

外径OD(mm) | SCH40(6m/5.8m) | SCH40(6m/5.8m) | SCH40(6m/5.8m) |

| 壁厚WT | 壁厚WT | 壁厚WT | ||

| (mm) | (mm) | (mm) | ||

| 1/4'' | 13.7 | 2.24 | 3.02 | / |

| 3/8'' | 17.1 | 2.31 | 3.2 | / |

| 1/2'' | 21.3 | 2.77 | 3.73 | 4.78 |

| 3/4'' | 26.7 | 2.87 | 3.91 | 5.56 |

| 1'' | 33.4 | 3.38 | 4.55 | 6.35 |

| 1-1/4'' | 42.2 | 3.56 | 4.85 | 6.35 |

| 1-1/2'' | 48.3 | 3.68 | 5.08 | 7.14 |

| 2'' | 60.3 | 3.91 | 5.54 | 8.74 |

| 2-1/2'' | 73 | 5.16 | 7.01 | 9.53 |

| 3'' | 88.9 | 5.49 | 7.62 | 11.13 |

| 3-1/2'' | 101.6 | 5.74 | 8.08 | / |

| 4'' | 114.3 | 6.02 | 8.56 | 13.49 |

| 5'' | 141.3 | 6.55 | 9.53 | 15.88 |

| 6'' | 168.3 | 7.11 | 10.97 | 18.26 |

| 8'' | 219.1 | 8.18 | 12.7 | 23.01 |

| 10'' | 273 | 9.27 | 15.09 | 28.58 |

| 12'' | 323.8 | 10.31 | 17.48 | 33.32 |

| 14'' | 355.6 | 9.53 | 11.13 | 19.05 |

| 16'' | 406.4 | 9.53 | 12.7 | 21.44 |

| 18'' | 457 | 9.53 | 14.27 | 23.83 |

| 20'' | 508 | 9.53 | 15.09 | 26.19 |

| 24'' | 610 | 9.53 | 17.48 | 30.96 |

Technical data

Structural Steel Pipe Chemical Composition and Mechanical Properties

| Standard | Grade | Chemical Composition (%) | Mechanical Properties | ||||||

| ASTM A53 | C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | ||

| A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 | ||

| B | ≤0.30 | - | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | ||

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 | |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | ||

| ASTM A179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| API 5L PSL1 | A | 0.22 | - | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 | |

| B | 0.28 | - | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | ||

| X42 | 0.28 | - | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | ||

| X46 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | ||

| X52 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | ||

| X56 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | ||

| X60 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | ||

| X65 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | ||

| X70 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | ||

| API 5L PSL2 | B | 0.24 | - | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 | |

| X42 | 0.24 | - | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | ||

| X46 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | ||

| X52 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | ||

| X56 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | ||

| X60 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | ||

| X65 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | ||

| X70 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | ||

| X80 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | ||

Structural Steel Pipe Chemical Composition and Mechanical Properties

| Standard | Grade | Chemical Composition | Mechanical Properties | |||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | ||

| GB/T8163 | 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.25 | ≤0.25 | 335-457 | ≥205 | ≥24 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 | 410-550 | ≥245 | ≥20 | |

| Q345 | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | ≤0.045 | ≤0.045 | - | - | - | 490-665 | ≥325 | ≥21 | |

Structural Steel Pipe Tolerance

| Pipe types | Pipe Szie(mm) | Tolerances | |

| Hot rolled | OD | All | ±1% (min ±0.50mm) |

| WT | All | +15%, -12.5% | |

| Cold drawn | OD | 6~10 | ±0.20mm |

| 10~30 | ±0.40mm | ||

| 30~50 | ±0.45mm | ||

| >50 | ±1% | ||

| WT | ≤1 | ±0.15mm | |

| >1~3 | +15% -10% | ||

| >3 | +12.5% -10% | ||

Structural Steel Pipe End

| Plain End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Plain End (Square Cut) | Wall Thickness over 0.5 inch, including SCH XXS |

| Beveled End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Couplings | Outside Diameter equal or less than 2'' |

| Thread Protection | Outside Diameter over 4 inch |

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Quality inspection

Advanced testing equipment and methods are used to conduct comprehensive testing of key indicators such as size, hardness, and toughness of the product. Track the entire production process to ensure that every process meets quality requirements

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision Processing, auto parts, machinery, electronic products, molds, medical equipment, construction, decoration, etc.

CUSTOMER VISIT

Due to our continuous and widespread success in overseas market and outstanding social contributions, our company was awarded by the local government for many times. Our products have been exported to Southeast Asia, Middle east, South America, Europe, Oceania and other countries and regions, which enjoys good reputation.

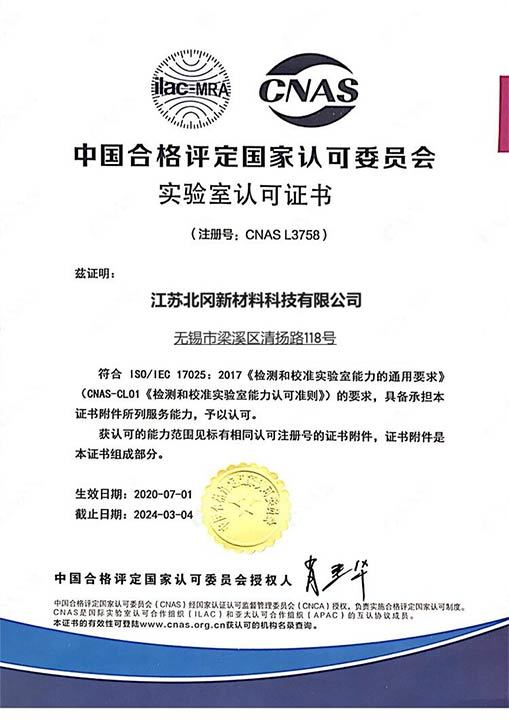

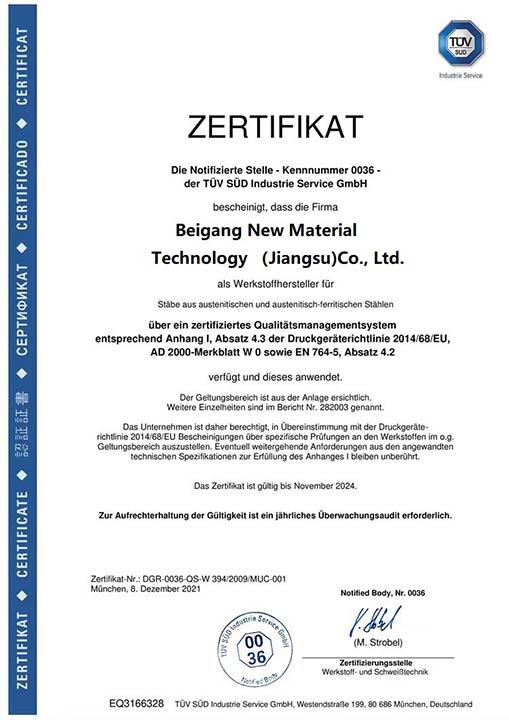

QUALIFICATION CERTIFICATES AND HONORS

FAQ

Q: What is your MOQ?

Q: What is the delivery time?

Q: What kind of payment terms would you accept?

Q: What certifications do your products have?

Q: Do you provide samples Is it free or extra?

Q: Once the products received by customer were found not comply with the products or contract demands, what will you do?

RELATED PRODUCTS

GET A FREE QUOTE