Anti-corrosion spiral steel pipe

Classification :

PRODUCT DETAILS

Keywords: Steel Plate, Steel Coil , Ductile Iron Pipe

The anti-corrosion spiral steel pipe is a type of steel pipe with excellent corrosion resistance. It uses high-quality steel as the base material and undergoes special anti-corrosion treatment processes such as coating with anti-corrosion coatings, hot-dip galvanizing, or spraying with polyethylene to enhance its corrosion resistance. This type of steel pipe is typically produced using spiral welding techniques, hence it is also known as spiral welded anti-corrosion steel pipe.

The anti-corrosion spiral steel pipe features corrosion resistance, wear resistance, and a long service life, making it suitable for conveying pipeline systems in industries such as chemical, petroleum, natural gas, and water conservancy. It effectively withstands corrosion from atmospheric, soil, and water media, as well as certain pressures and temperature changes, ensuring the safe operation of pipeline systems.

Due to its excellent anti-corrosion performance and reliability, the anti-corrosion spiral steel pipe is widely used in various engineering projects, including oil and gas transmission, drainage, and sewage disposal, among others.

|

Product Name |

Anti-corrosion spiral steel pipe |

|

Size |

Outer Diameter: 50mm-3600mm |

|

Surface |

Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Fusion Bond Epoxy, 3LPE) |

|

Process: |

LSAW (Longitudinal Submerge-arc Welded) UO(UOE),RB(RBE),JCO(JCOE) |

|

Steel Grade: |

GB/T3091, SY/T5037, SY/T 5040,CJ/T 3022:Q195, Q215, Q235, Q275, Q295, Q345, 08F, 08, 08AL, 08F, 10F, 10, HG5, DF08 SPHC, M8 |

|

Application |

Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose |

|

Standard |

BS EN GB AiSi ASTM DIN JIS |

|

Packing |

Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps. |

|

Test: |

Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test. |

|

MOQ |

5 TONS |

|

Delivery |

7 to 25 working days after the receipt of 30% deposit |

|

Payment |

30%TT for deposit, 70% balance before shipment or LC at sight |

Internal FBE Coating

|

DN (mm) |

FBE (μm) |

|

100~500 |

>350 |

|

550~750 |

>400 |

|

≥800 |

>450 |

External 3PE Coating

|

N.B |

Epoxy powder coating |

Adhesive(μm) |

Min wall thickness of anticorrosive coating |

||

|

|

|

two layer |

three layer |

usual grade |

|

|

≤100 |

≥80 |

200-400 |

170-250 |

1.8 |

|

|

100 |

≥80 |

200-400 |

170-250 |

2.0 |

|

|

250 |

≥80 |

200-400 |

170-250 |

2.2 |

|

|

500 |

≥80 |

200-400 |

170-250 |

2.5 |

|

|

DN≥800 |

≥80 |

200-400 |

170-250 |

3.0 |

|

Packing and shipping

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Quality inspection

Advanced testing equipment and methods are used to conduct comprehensive testing of key indicators such as size, hardness, and toughness of the product. Track the entire production process to ensure that every process meets quality requirements

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision Processing, auto parts, machinery, electronic products, molds, medical equipment, construction, decoration, etc.

CUSTOMER VISIT

Due to our continuous and widespread success in overseas market and outstanding social contributions, our company was awarded by the local government for many times. Our products have been exported to Southeast Asia, Middle east, South America, Europe, Oceania and other countries and regions, which enjoys good reputation.

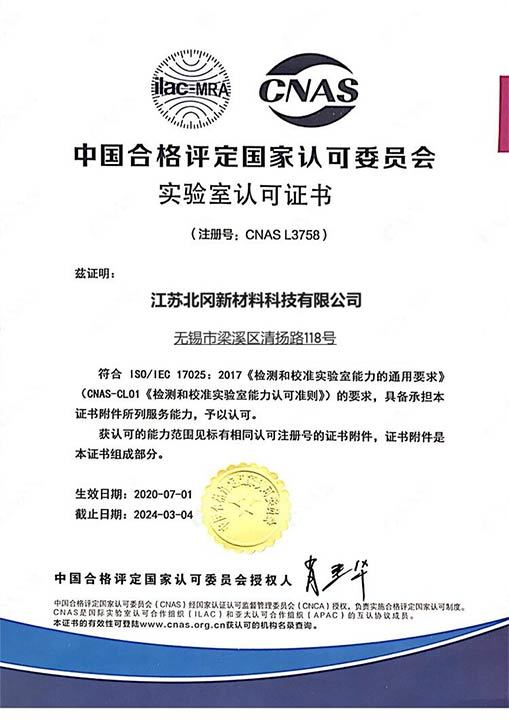

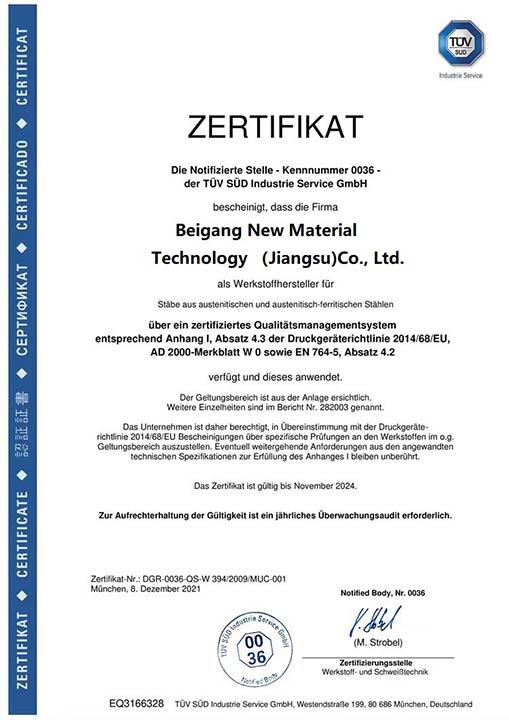

QUALIFICATION CERTIFICATES AND HONORS

FAQ

Q: What is your MOQ?

Q: What is the delivery time?

Q: What kind of payment terms would you accept?

Q: What certifications do your products have?

Q: Do you provide samples Is it free or extra?

Q: Once the products received by customer were found not comply with the products or contract demands, what will you do?

RELATED PRODUCTS

GET A FREE QUOTE